packaging

REDEFINING RESPONSIBLE PACKAGING IN MODERN LUXURY

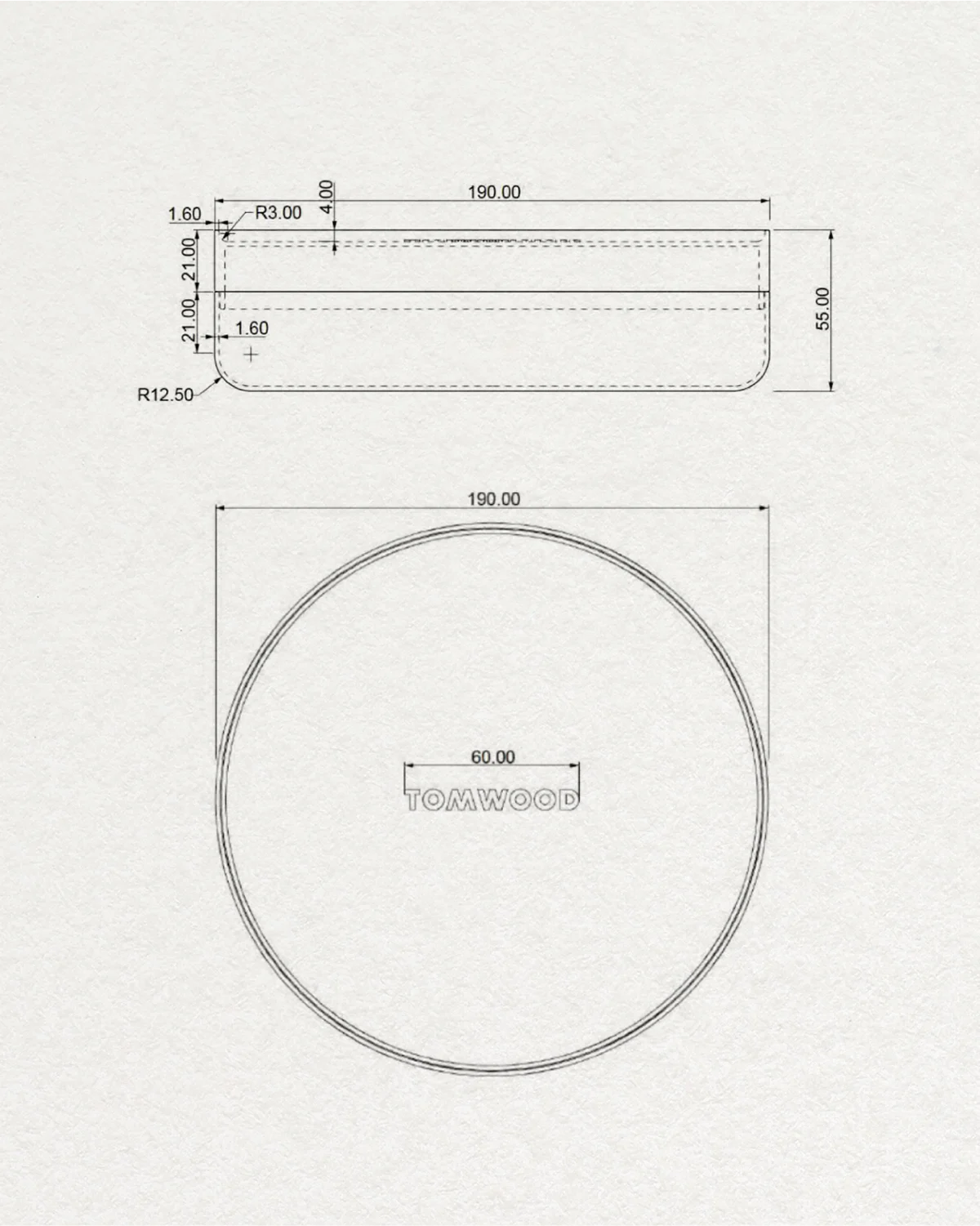

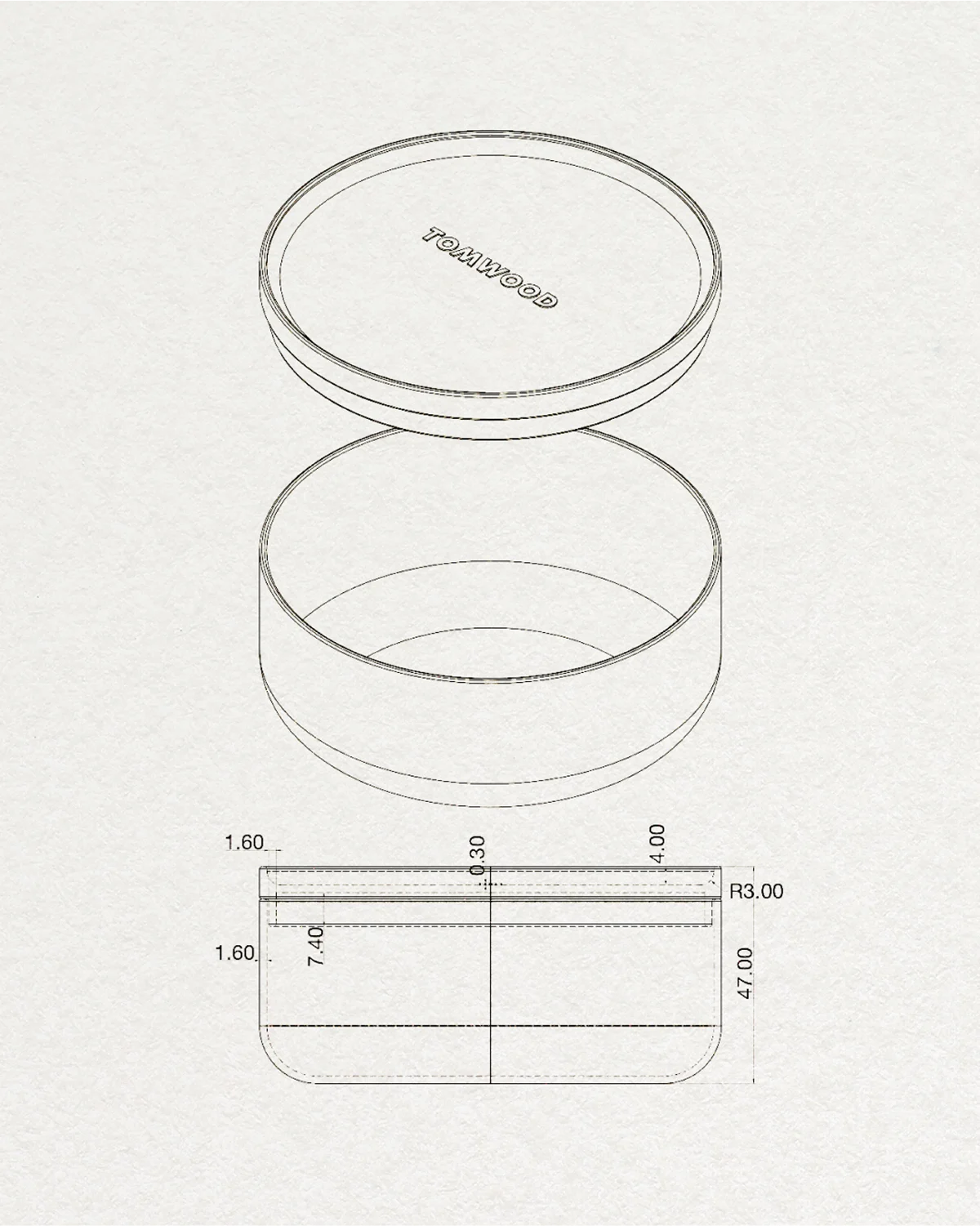

The launch of our new jewellery box is a testament to our commitment and progress, while removing plastics from our cycle. Now made from 100% recycled aluminium - an embodiment of uncompromising craftsmanship.

COMMITMENT

Driven by an ambition for continuous improvement and innovation, we embarked on a journey to redefine how a jewellery box could be developed, produced, and experienced.

Simultaneously, we aimed to significantly reduce carbon emissions and eliminate recycled plastic from its cycle, where the previous jewellery boxes accounted for the majority of this impact.

This packaging project has been an incredibly demanding yet inspiring journey, countless rounds of meticulous process adjustments, studying our boxes with the same intensity and attention to detail as our jewellery. Collaborating closely with some of the finest partners in the industry, from raw material suppliers to production partners, has truly elevated our ambition and brought this vision to life.

VISION

The new packaging programme brings together 100% recycled, responsibly sourced, and certified components across every touchpoint. From gift and e-commerce boxes to cards and paper bags. Each element has been developed and re-sized with care to minimise impact to an absolute minimum while maintaining the quality and precision Tom Wood is known for.

A third-party Carbon Footprint Assessment found that our newly introduced 100% recycled aluminium jewellery box has a significantly lower carbon footprint than our previous 100% recycled PET (rPET) box. The assessment was conducted using ISO-compliant Life Cycle Assessment (LCA) methodology, comparing our new jewellery boxes, manufactured via a cold stamping process in China, to our previous 100% recycled PET (rPET) box, produced via injection molding.

Based on enterprise-specific data, the aluminium box reduces Global Warming Potential (GWP) by 6.4–9.9% per unit compared to rPET, and by approximately 25% on a per-kilogram basis according to Chinese industry averages. Furthermore, sensitivity and uncertainty analysis confirmed that, under a wide range of real-world scenarios, the aluminium box consistently outperforms rPET in carbon performance, with a reduction of up to 0.6 kg CO₂e per kilogram. These results highlight recycled aluminium’s superior potential for climate impact reduction, especially as production efficiency improves. Tom Wood is now conducting its own LCA to further substantiate these findings at product-level granularity.

Responsibility and innovation drive everything we do at Tom Wood, and our new packaging is no exception. By transitioning from rPET to 100% recycled aluminium, we’ve eliminated plastics from our packaging and embraced a future-forward material with superior environmental performance. Backed by third-party LCA research, this shift reduces carbon emissions by up to 25% per kilogram, while preserving our uncompromising standards for quality and design.

It’s a bold step that sets a new industry benchmark, proving that refined craftsmanship and real climate action are not only compatible, but essential.

The new jewellery boxes launched June 18th 2025, the new packaging will be available in all Tom Wood Flagship stores in Oslo, Aoyama and Dover Street Market Ginza, online at www.tomwoodproject.com, and in selected retailers worldwide.

Read more about the Comparative Carbon Footprint Assessment.